AI Vision Glove Defect Inspection System > Selangor > Malaysia

In order to ensure the safety and efficacy of medical gloves for use in procedures, it is essential to identify and correct any defects, such as holes, tears, or weak spots, before they are shipped to customers. Currently, the standard method for inspecting glove quality involves employing 30 manual laborers to visually inspect each glove for defects.

Estimated ROI

1.5-2 years

Solution

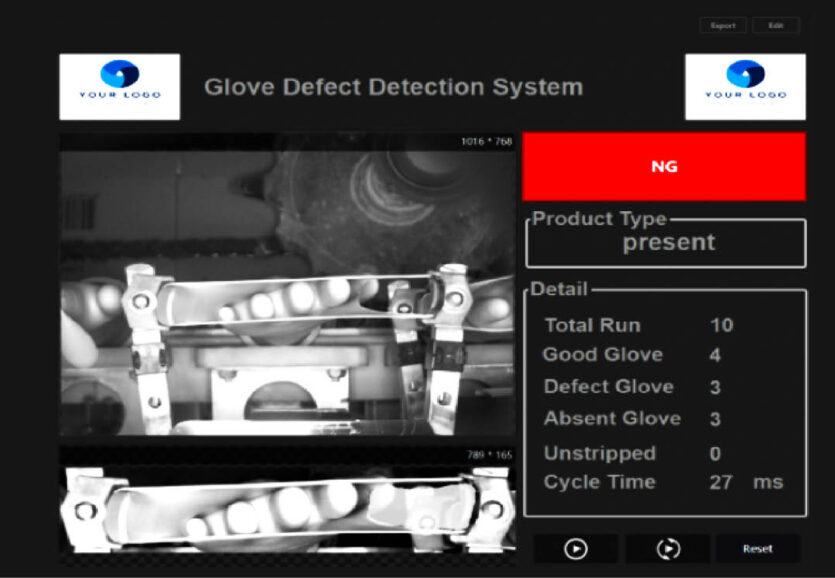

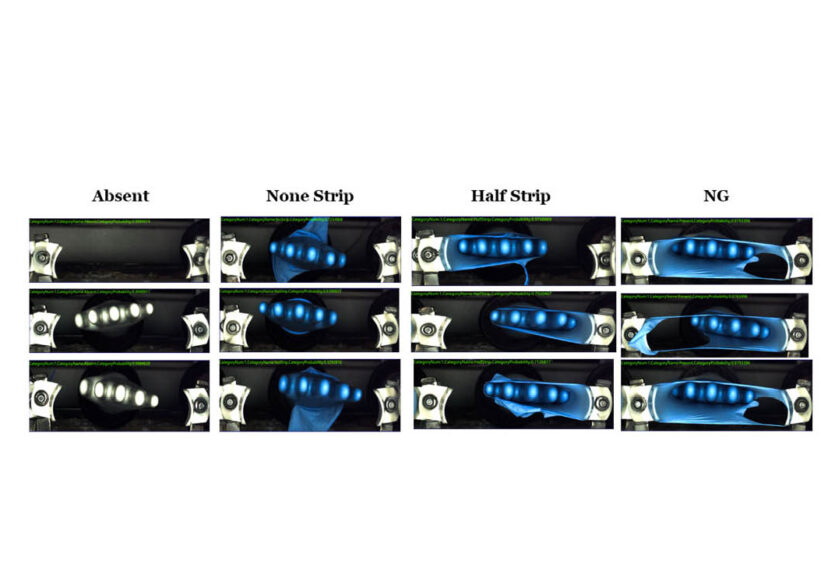

Our team has developed a solution to improve the quality inspection process using AI deep learning to train a computer vision system. This algorithm is designed to identify any holes or tears in each glove following production, and has achieved a remarkable 99.86% accuracy rate for detecting defects in the production of medical gloves.

The AI vision system also has the ability to detect and categorize defects caused by the auto-stripping machine, which includes torn cuffs, broken beading, and half-strips. If a defective glove is detected, it will be rejected by the roller type unloader machine. In addition, the system is designed to detect an empty former and an un-strip/half-strip glove, which cannot be unloaded by the roller type unloader machine. To address this issue, a counter with light indicators and an alarm will be installed at the end of the dipping line to alert operators to standby and remove the defective gloves.

Given that un-strip/half-strip gloves are rare in normal production, we intend to station a well-trained operator to collect any gloves that fail to reject on the 4 production lines. This will be achieved using a digital counter display as a notification system.

Location

Klang Valley, Selangor, Malaysia

#AI Vision Inspection #Product Quality Inspection #Klang Valley #Selangor #Malaysia